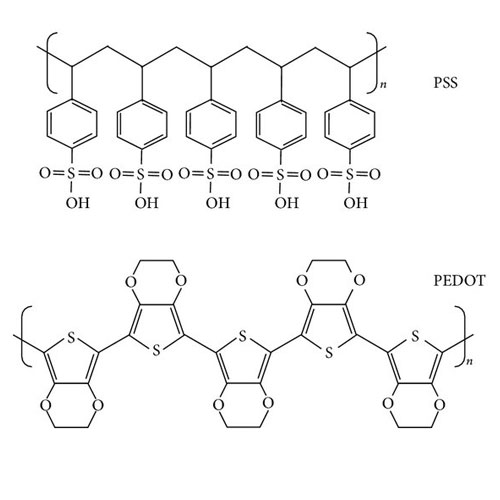

PEDOT:PSS (or Poly(3,4-ethylenedioxythiophene) polystyrene sulfonate, CAS 155090-83-8) is a transparent conductive polymer. It is a mixture of the ionomer poly(3,4-ethylenedioxythiophene), carrying positive charges, and polystyrene sulfonate, carrying negative charges. Due to its unique combination of conductivity, transparency, ductility, and ease of processing, PEDOT:PSS has become a benchmark material in thin-film electronic fabrication. There are many types of PEDOT dispersions, including PEDOT:PSS AI 4083 and PEDOT:PSS PH 1000.

DESCRIPTION

General description

Poly(3,4-ethylenedioxythiophene)-poly(styrenesulfonate) (PEDOT:PSS) is an organic semiconductor prepared by doping cationic poly(3,4-ethylenedioxythiophene) and poly(4-styrenesulfonate) anion. Its high electrical conductivity and good oxidation resistance make it suitable for electromagnetic shielding and noise suppression. PEDOT:PSS based polymeric films have a high transparency throughout the visible light spectrum and even in near IR and near UV regions, with virtually 100% absorption from 900-2000 nm. PEDOT provides the conduction properties and PSS forms a hydrated colloidal solution.

We are committed to bringing you Greener Alternative Products, which adhere to one or more of the 12 Principles of Green Chemistry. This product is used in energy conversion and storage, thus has been enhanced for energy efficiency. Click here for more information.

Application

Electrical conductivity measurements herewith reported were on a film deposited by spin-coating on a clean glass, then dried (130 °C for 15 minutes on a hotplate). The layer thickness was determined by scratching the layer and measuring the profile/height of the scratch by a stylus profilometer. Electrodes for the measurement were by evaporating metal contacts (four-point probes).

PEDOT:PSS is an intrinsically conductive polymer (ICP) that can be coated on various substrates and nanostructures like fullerenes (C60) to form composites with high electrochemical properties for applications like low-cost printed electronics, optoelectronics, and polymeric solar cells. It can be used as a conductive hydrogel with polyethylene glycol-diacrylate (PEG-DA) for potential applications in tissue engineering. PEDOT:PSS also finds use in other organic electronic applications like organic thin film transistors (OTFTs) and dye sensitized solar cells (DSSCs).

Ready-to-use high conductivity coating formulation.

Virtually 100% absorption from 900-2,000 nm. No absorption maximum from 400-800 nm. Conductive polymer blend.

Packaging

Packaged in poly bottles

In organic light emitting diodes, organic photovoltaics, and perovskite photovoltaics, PEDOT:PSS can be used as an interfacial layer for hole transport. It can also be used as a replacement for transparent conductors such as ITO or FTO. Commonly, it is used in applications where the underlying substrate is flexible.

The properties of PEDOT:PSS vary between dispersions, hence its versatility. The key properties of PEDOT:PSS are its conductivity and the size of its work function. Since PEDOT is conductive and PSS is insulating, the conductivity of the resulting polymer depends on the ratio between the two ionomers and the microstructure of the film. Similarly, a higher presence of PSS at the surface will result in a deeper work function.

PEDOT:PSS is typically available as a water-based emulsion. It is created via the polymerization of PEDOT monomers in a polystyrene sulfonic acid solution. We supply all our PEDOT:PSS solutions in light resistant bottles with temperature indicators.

All PEDOT:PSS and PEDOT Complexes

Choosing the right PEDOT product for you could be a difficult task. Each has a different base solvent, conductivity, viscosity, and even composition. At Chembourn, we have a range of PEDOT:PSS and PEDOT:Complex products. They are available in different solvents for applications in OLED, OPV, and sensors, and are suitable for different deposition methods, i.e. spin coating, inkjet printing and screen printing.

Applications of PEDOT:PSS

PEDOT:PSS is the subject of a considerable amount of research and is used for a range of applications within thin-film electronic fabrication. This includes perovskite photovoltaics, organic photovoltaics, organic light emitting diodes, transparent conductors, organic electrochemical transistors, flexible electronics, thermoelectric generators, supercapacitors, and energy storage.

Perovskite Photovoltaics

PEDOT:PSS has been used as a hole extraction material in inverted devices. This material facilitates the extraction of charge carriers at the interface between the transparent conductive oxide and the active perovskite layer. Inverted perovskite devices using PEDOT:PSS typically show lower hysteresis than standard architecture devices. In addition, recent work on standard architecture devices shows that the toluene-based PEDOT:PSS can be used as a cheap alternative to Spiro-OMeTAD.

Organic Photovoltaics

PEDOT:PSS has long been used as a standard material in device fabrication. It has been extensively used with materials such as P3HT and PCDTBT to form the backbone of fundamental research into polymer solar cells. In addition, PEDOT:PSS is being used in combination with state-of-the-art organic photovoltaic materials to push new efficiency limits.

Organic Light Emitting Diodes

The use of PEDOT:PSS in organic light emitting diodes, as a well-established standard hole injection material, has been widespread for over a decade. Recent work still uses PEDOT:PSS due to its deep work function. This allows for efficient charge injection into white emitting polymers as well as host materials for thermally activated delayed fluorescence materials.

Transparent Conductors

PEDOT:PSS is a potential replacement for expensive transparent metal oxides, such as ITO and FTO. Its effectiveness in both organic photovoltaic and perovskite photovoltaic devices has been demonstrated. In addition, in combination with metallic grid structures, it is possible to achieve sheet resistances comparable to metallic films.

Substrate surfaces should be prepared before the deposition of PEDOT:PSS to ensure that they are clean. This can be done using deionised (DI) water, Hellmanex III, isopropyl alcohol and a UV ozone cleaner. Once the surface is ready, a PEDOT:PSS thin film can be formed using a spin coater.

Thin Film Deposition of PEDOT:PSS

For the deposition of thin films of PEDOT:PSS on a freshly prepared surface, we recommend using a vacuum-free spin coater and following this five-step process:

Filter your PEDOT:PSS solution through a 0.45 µm PES filter (or hydrophobic PTFE filter for HTL Solar 3) into an amber vial.

Preheat a hot plate to 120 °C.

Place your freshly prepared substrate into an Ossila Spin Coater and set to the desired spin speed.

The substrates should be spun until the films are dry; for PEDOT:PSS films this is typically >30 seconds.

Once the spin coating has finished, place the samples on a hotplate for 15 minutes to fully dry.

For speeds below 1000 rpm we recommend static spin coating. For higher speeds, dynamic spin coating can be used.

Obtaining a Uniform Coating

The coating quality of the PEDOT:PSS is dependent on several factors. These include the PEDOT formulation you are using, the deposition technique, the surface you are depositing onto, and the cleanliness of the surface. Ideally, the film should be highly uniform across the entire surface although variations at the ends of your sample can occur due to edge effects.

Due to the wetting conditions of the PEDOT formulation on the surface, the coating may not always be uniform. If this occurs there are several things that can be done. The first is to ensure that the surface of your sample is clean, if possible use a combination of solvent cleaning steps and UV ozone or oxygen plasma treatments to ensure a completely clean surface. If this does not improve the quality of the surface, secondary solvents can be added. For AI 4083 and PH 1000, the addition of approximately 10% isopropanol can improve the wetting on surfaces.

Frequently Asked Questions

What Makes PEDOT:PSS Conductive?

The electrical conductivity of oxidized polythiophenes has been known for nearly 40 years. The presence of radical states, which are formed due to the oxidation of thiophene units, is the origin of this conductivity. These reduced states are delocalized across the polymer chain, and in the presence of the oxidizer, these radicalized states can be stabilized.

In PEDOT:PSS, the PEDOT is oxidized by the polystyrene sulfonate during the polymerisation reaction. This produces an emulsion in which the PSS pstabilizes the radical states on the PEDOT.

Although PEDOT is conductive, PSS is insulating. The quantity of PSS and the microstructure of the film have a significant impact on the electronic properties of PEDOT:PSS. In a water-based dispersion, the PEDOT and PSS form a micelle structure in which the hydrophobic PEDOT core is surrounded by a shell of hydrophilic PSS. This structure is retained during deposition and forms localized regions of conductive PEDOT surrounded by insulating regions of PSS. It is this core-shell structure which results in the low conductivity values that can arise for standard formulations of PEDOT:PSS.

Can the Conductivity of PEDOT:PSS be Improved?

Advanced formulations offer increased conductivity of PEDOT:PSS thin films. This is achieved by the addition of, or exposure to, secondary solvents (sometimes referred to as secondary dopants).

It was originally believed that these solvents acted by further doping the PEDOT, hence the name secondary dopant. More recent work has revealed that their presence alters the core-shell structure. When exposed to these solvents, the hydrophilic/hydrophobic nature of the PSS/PEDOT components no longer determine the structure. The solvents allow the diffusion and intermixing of the PEDOT and PSS chains, creating a more homogenous film on the microscale. This homogenisation increases the path length of charges along the PEDOT chain, reducing the distance that charges must travel across PSS rich areas.

What Determines the Work Function of PEDOT?

As work function is a surface property of a material, the work function of the PEDOT:PSS blend is determined by the percentage of each component at the surface of the film. PSS has a significantly deeper work function than PEDOT, therefore a higher presence of PSS at the surface will result in a deeper work function. In formulations with higher percentages of PSS, the work function will be higher than those with lower percentages.

In addition, the processing of the PEDOT:PSS film can result in changes to the work function. When the core-shell structure is formed, PEDOT is surrounded by PSS. In this case, the work function will be dominated by PSS. If the film has been treated and the components are more homogenously dispersed, the work function will become shallower as the surface becomes richer with PEDOT.

How Should PEDOT Materials be Stored?

The recommended storage temperature of PEDOT:PSS and PEDOT dispersions is between 5 and 10 °C. It is recommended that you store the dispersion at the front of a refrigerator. The product is not usable if frozen, so should be kept away from the back of the refrigerator.

The dispersions can tolerate up to a week outside of the refrigerator (e.g. during shipping) without negative consequences for the PEDOT:PSS performance. Over time at elevated temperatures, the PEDOT:PSS can phase separate, aggregate, and form a solid that drops to the bottom of the bottle, reducing performance. Brief heating to a maximum of 50 °C has no adverse effect on product properties.

What is the Shelf Life of PEDOT Materials?

When stored at 5 to 10 °C, the PEDOT dispersion will give you consistent performance over 12 months if used regularly. The official recommended shelf life from the manufacturer is 9 months after production if the dispersion is never used or disturbed. After this time, the dispersion will gradually separate or sediment at a very slow rate, resulting in lower concentrations and thinner films.

Material degradation is mitigated by frequent use of the dispersion due to the gentle agitation when decanting. Through constant use, it is possible to use a single bottle of PEDOT:PSS for many years without harming device performance.

E-mail: info@chemborun.com

E-mail: info@chemborun.com Tel: +86-574-87178138

Tel: +86-574-87178138  No. 1558, Jiangnan Road,, Ningbo, Zhejiang, China (Mainland)/31

No. 1558, Jiangnan Road,, Ningbo, Zhejiang, China (Mainland)/31